A research team led by Academician Huang Wei and Professor Xin Hao from the National Key Laboratory of Flexible Electronics (Nanjing University of Posts and Telecommunications/School of Chemistry and Life Sciences) has made a significant breakthrough in copper-zinc-tin-sulfur-selenium (CZTSSe) thin-film solar cells. Their latest findings were published on September 15 (Beijing Time) in the international journal Nature Energy under the title “Solution-processed kesterite solar module with 10.1% certified efficiency” (DOI: 10.1038/s41560-025-01860-3). Nanjing University of Posts and Telecommunications (NJUPT) is the sole corresponding institution. Academician Huang Wei, Professor Xin Hao, and young faculty member Dr. Wang Shaoying are the corresponding authors, while doctoral student Xiang Chunxu and master’s student Yuan Mingjun are the co-first authors.

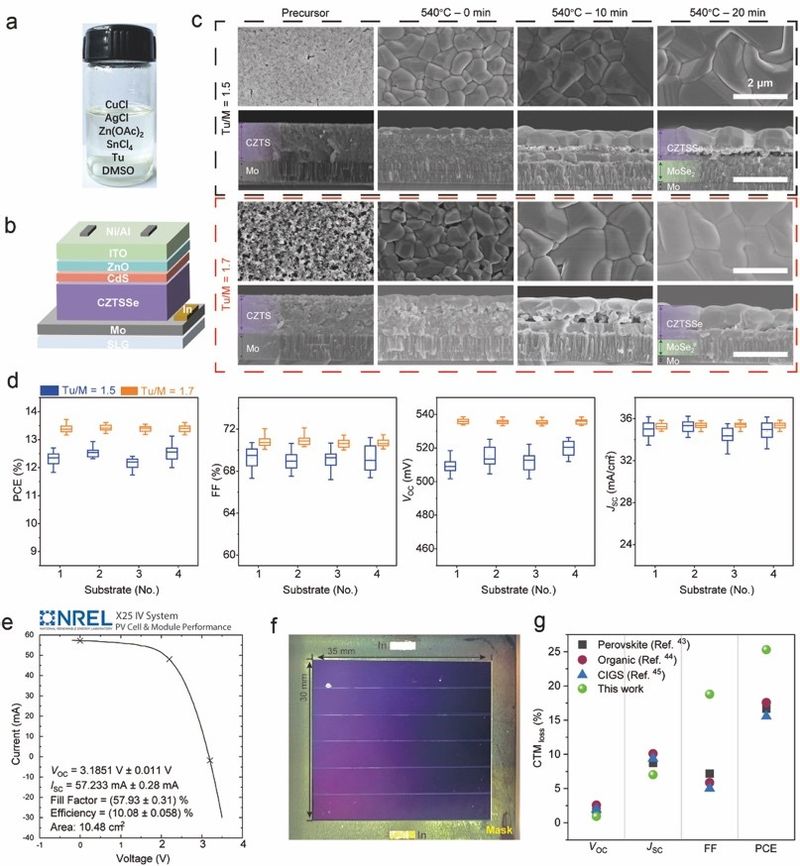

The team successfully fabricated large-area uniform CZTSSe thin films and record-efficiency solar modules via a solution-processing route. Their study identified the key factor limiting film uniformity-premature formation of a dense crystalline layer during selenization that hinders selenium vapor penetration. By tuning the thiourea-to-metal ratio (Tu/M from 1.5 to 1.7), they enhanced the porosity of precursor films, enabling deeper selenium diffusion and promoting both vertical crystallization and lateral grain growth. This approach significantly improved film homogeneity and smoothness, raising the average efficiency of single cells from 12.4% to 13.4% while reducing efficiency variation. Large-area films prepared under these conditions maintained excellent uniformity, yielding module efficiencies of 8.91%. Further optimization of device architecture reduced non-ideal contacts and resistive losses, enabling a certified module efficiency of 10.1% (active area: 10.48 cm²), as confirmed by the U.S. National Renewable Energy Laboratory (NREL). This achievement marks the first world record efficiency for a CZTSSe solar module.

(a) Photograph of precursor solution; (b) schematic diagram of the CZTSSe solar cell structure; (c) surface and cross-sectional SEM images of precursor films and absorber films prepared from different solution compositions (Tu1.5, Tu1.7) at various selenization stages; (d) statistical plots of photovoltaic parameters for Tu1.5 and Tu1.7 solar cells; (e) I–V curve of a CZTSSe module with an NREL-certified efficiency of 10.08%; (f) front view of the certified module; (g) comparison of CTM (Cell-to-Module) losses among thin-film solar modules, including perovskite, organic, CIGS, and CZTSSe modules.

Thin-film solar cells that can be processed at low cost over large areas have become a frontier in next-generation photovoltaics, with rapid advances in perovskite and organic solar cells. As a multicomponent inorganic compound with a kesterite structure, CZTSSe is composed of earth-abundant elements, features a high absorption coefficient, excellent stability, and high theoretical conversion efficiency, making it a promising candidate for solution-processed thin-film photovoltaics. However, unlike organic or perovskite films, which can directly form the target structure during solvent evaporation, solution-processed CZTSSe requires both precursor deposition and high-temperature selenization-steps that involve complex phase evolution and grain growth. Achieving large-area uniform films with high efficiency remains a major challenge for practical applications.

To address this challenge, the research team first investigated the root cause of the poor uniformity in CZTSSe films. They found that during the initial stage of selenization, a dense crystalline layer formed prematurely on the film surface, severely hindering selenium vapor penetration into the film. This resulted in compositional and crystallinity non-uniformities in both vertical and lateral directions. By adjusting the ratio of thiourea to metal in the precursor solution (increasing Tu/M from 1.5 to 1.7), the team effectively increased the porosity of the precursor films. The looser structure not only facilitated sufficient selenium diffusion throughout the film during selenization but also provided space for lateral grain growth. As a result, the film’s uniformity and surface smoothness were significantly improved, raising the average efficiency of single-junction devices from 12.4% to 13.4%, while reducing the standard deviation from 0.29% to 0.13%. Large-area CZTSSe films prepared under these conditions maintained excellent uniformity, delivering a module efficiency of 8.91%. Further optimization of the module architecture shortened current transport paths through the low-conductivity ITO channel and the high-resistance MoSe₂ layer, thereby improving the fill factor and overall efficiency. The module achieved a certified efficiency of 10.1% (active area: 10.48 cm²). Its CTM losses in open-circuit voltage and current density were both lower than those of perovskite, organic, and CIGS thin-film solar cells.

This work not only represents a major breakthrough for CZTSSe modules but also demonstrates the feasibility of producing large-area uniform multicomponent inorganic compound films via solution processing. It provides a clear and practical technical pathway for fabricating high-performance thin-film solar cells and modules, offering a viable approach to the industrialization of green and low-cost photovoltaic technologies.

This research was supported by the National Key R&D Program of China, the Major Basic Research Project of the Shandong Natural Science Foundation, the National Natural Science Foundation of China, and the Graduate Innovation and Practice Project of Jiangsu Province.

(Author: Xin Hao, Wang Shaoying; Initial Review: Qiao Zuqin, Dai Xiubin; Editor: Wang Hongcun; Review: Zhang Feng)